- Home

-

About

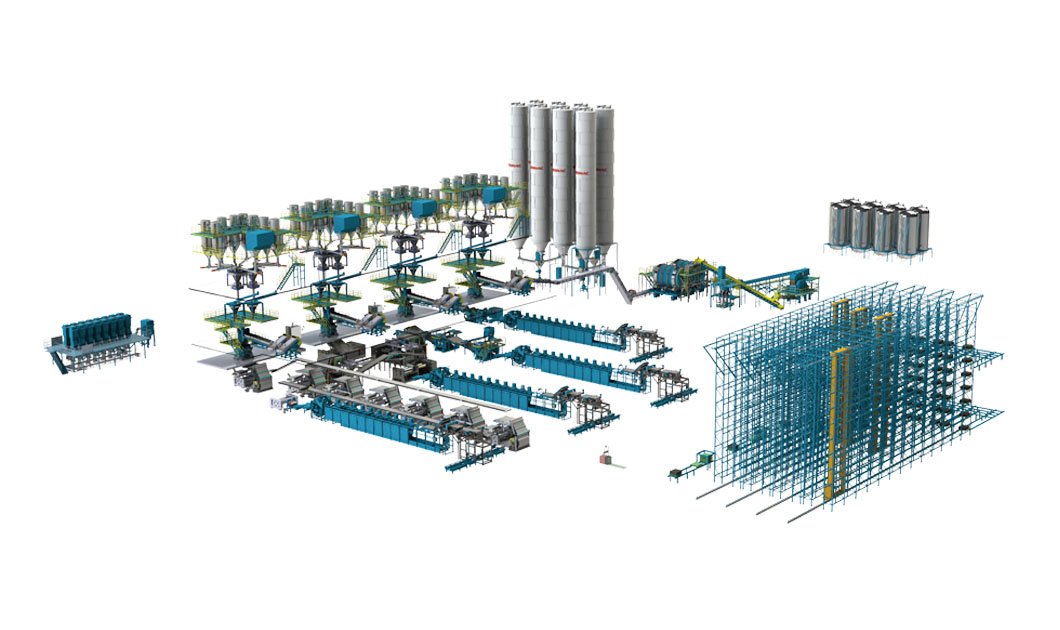

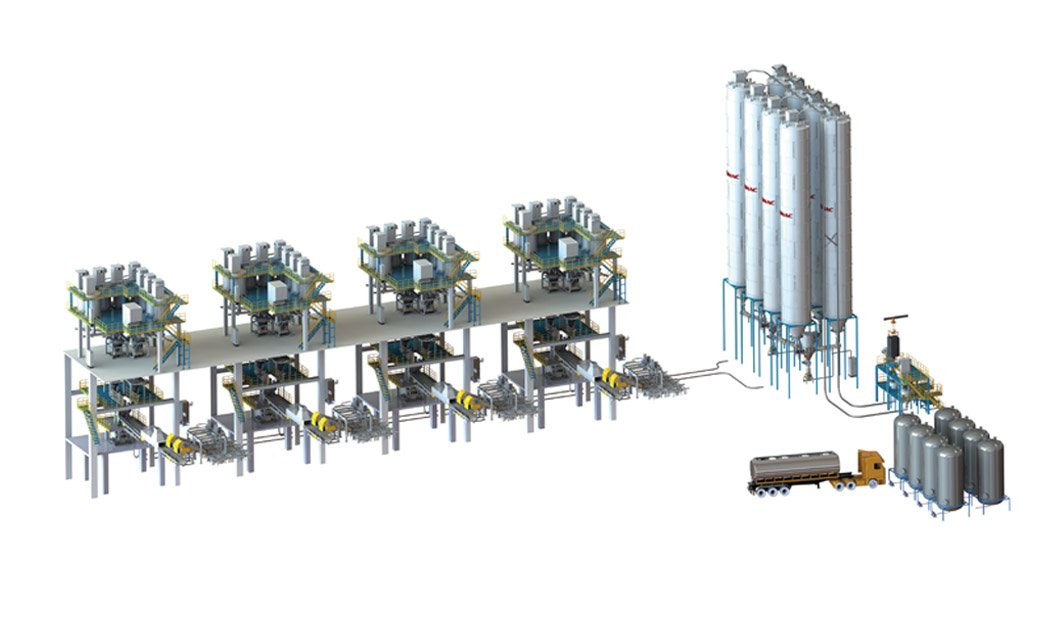

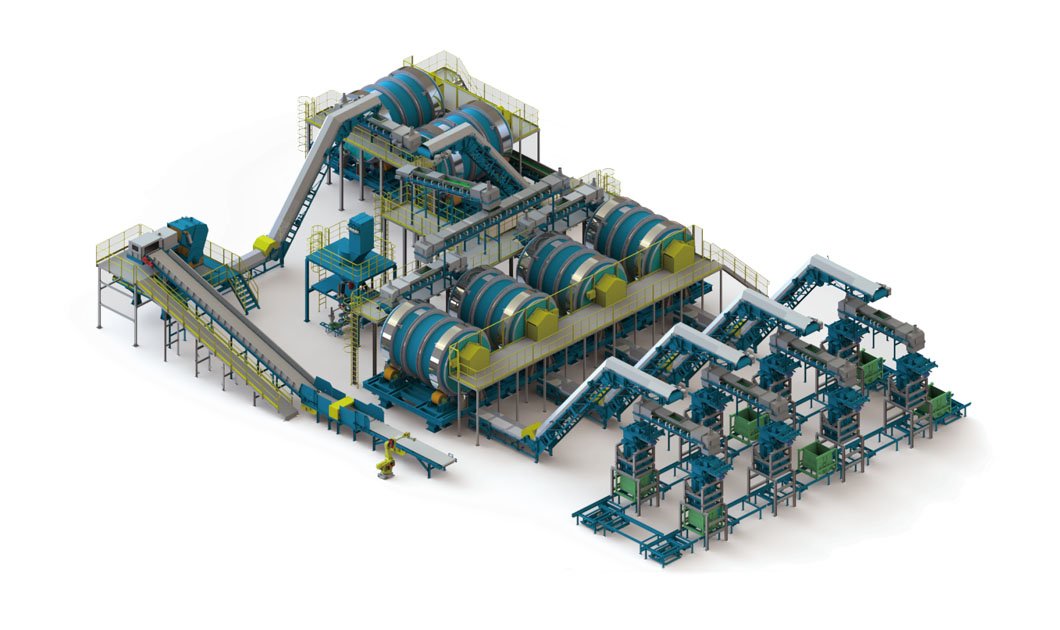

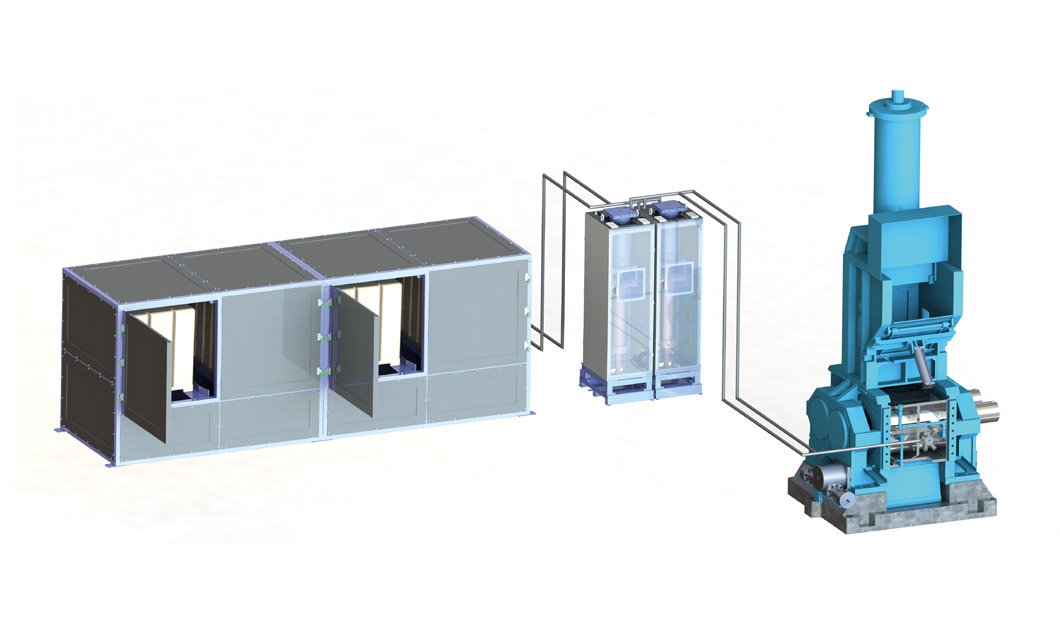

MESNAC Co., Ltd. was established in 2000. It is an international high-tech enterprise group developed by Qingdao University of Science and Technology.

- Sustainability

-

Solutions

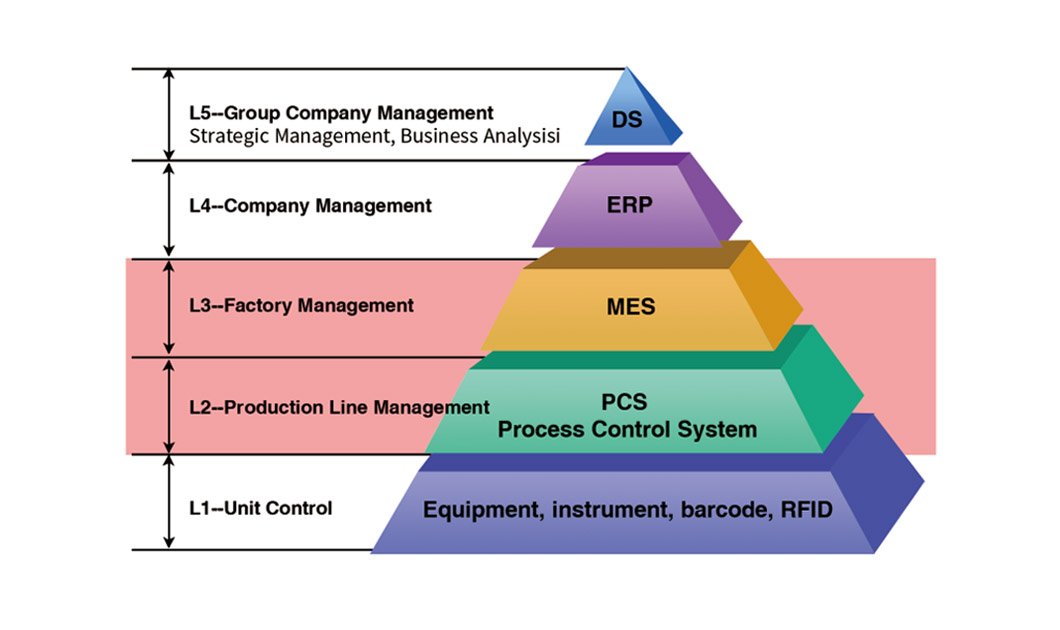

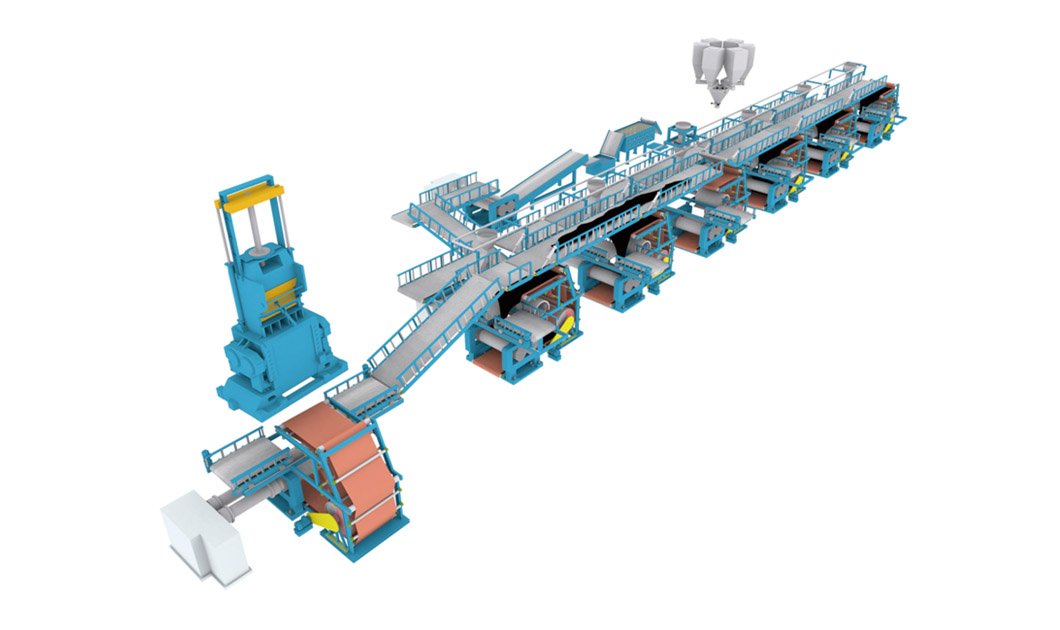

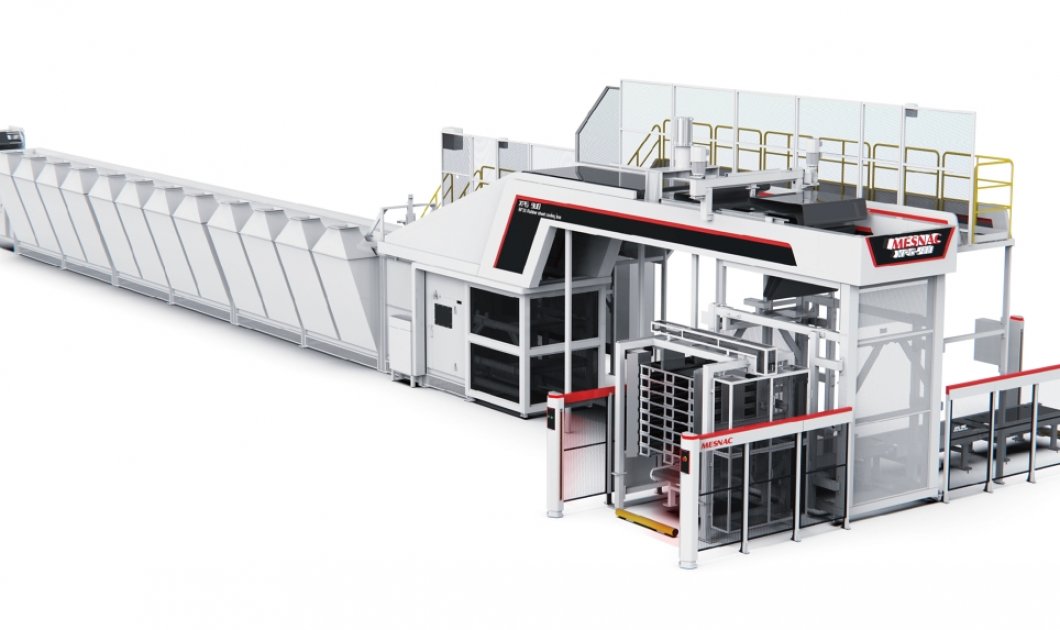

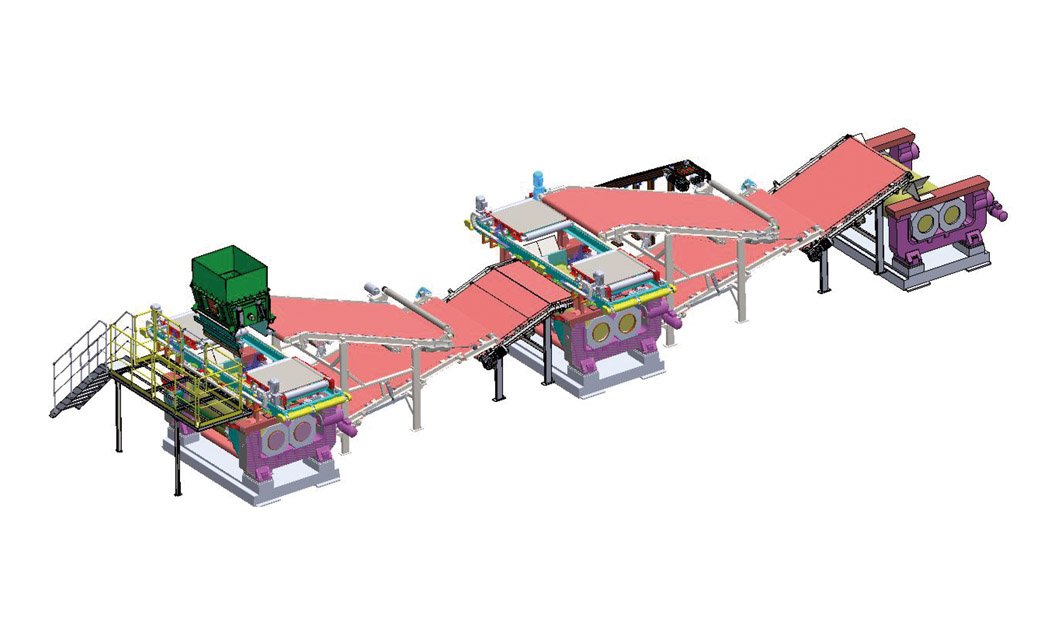

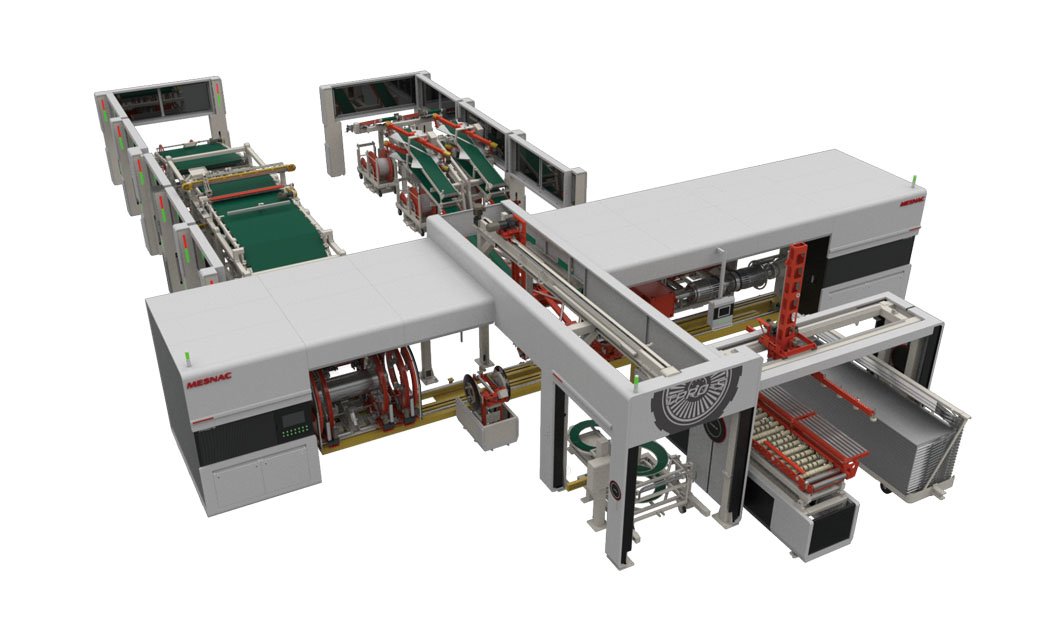

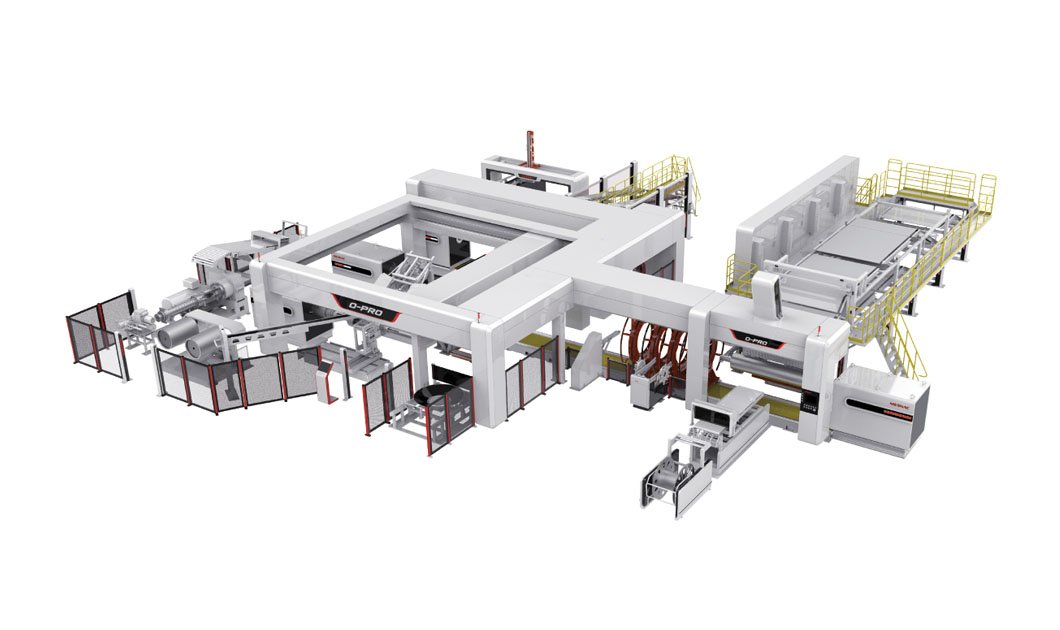

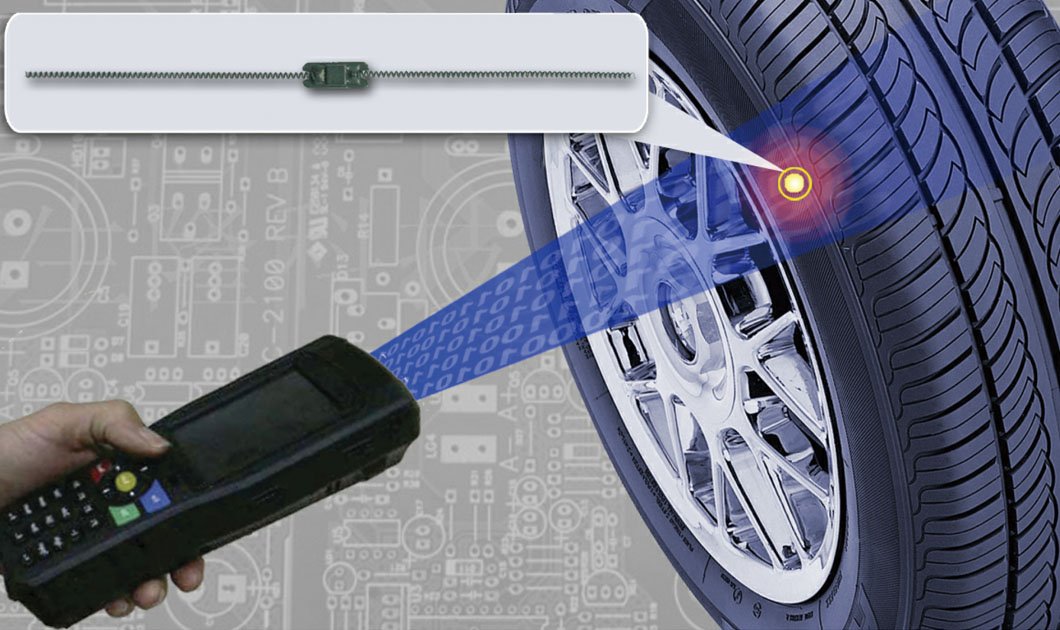

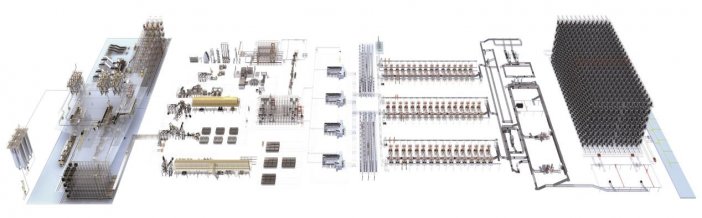

MESNAC's main business and technical advantages are concentrated in the field of rubber machinery, but also involved in the Internet of Things, new materials, energy conservation and environmental protection.

- News

-

Career

People-oriented, talent-based employment, Mesnac people are our most valuable assets.

一级标题

一级标题