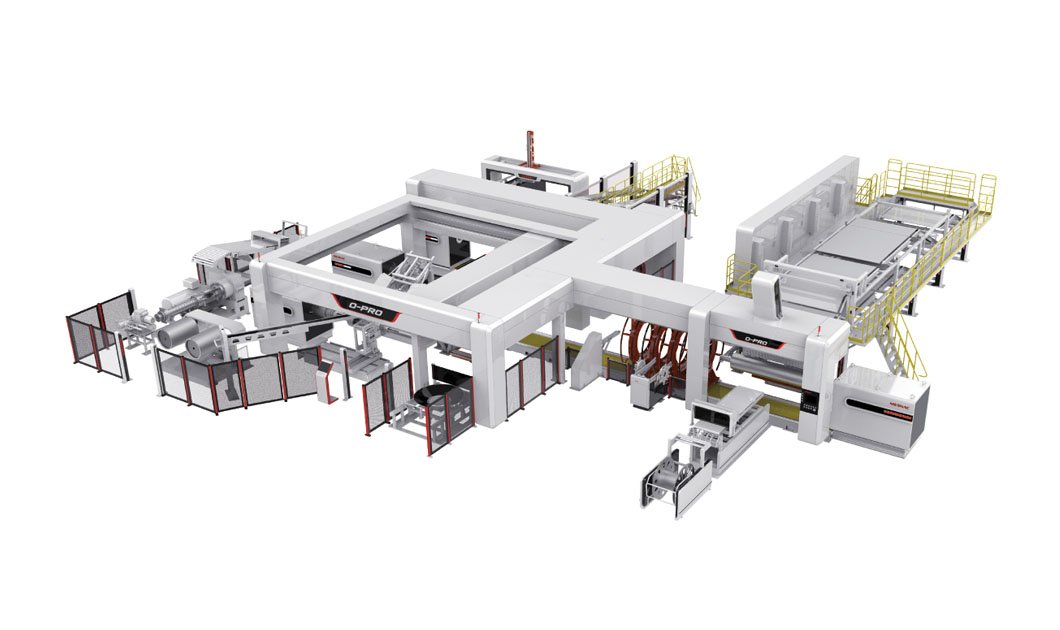

Smart tools:

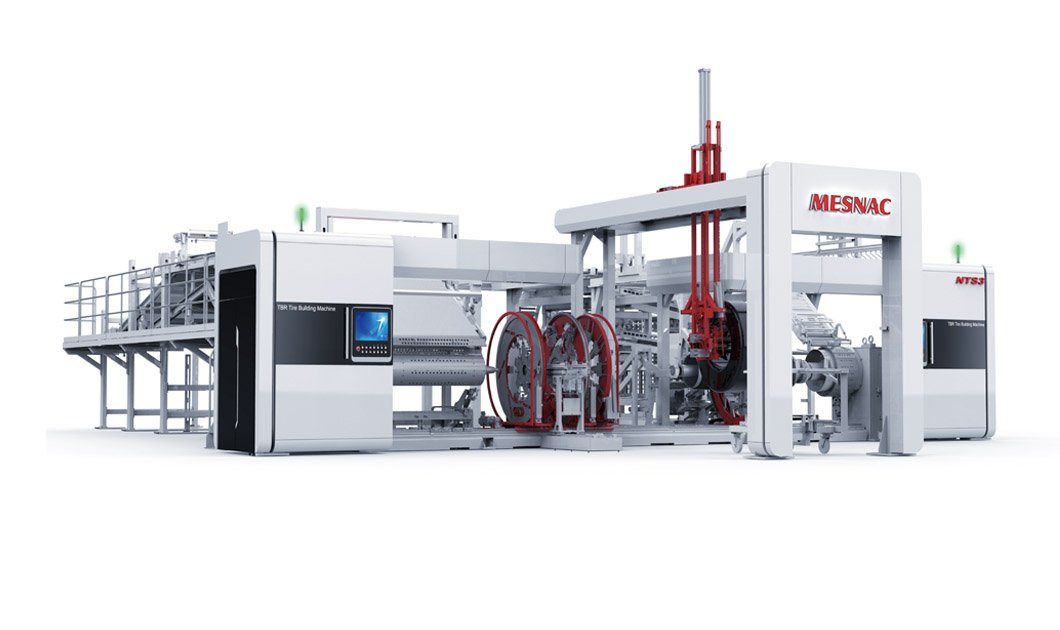

▶Belt drum expansion&collapsing is controlled by a servo motor.

▶Belt transfer ring expansion&collapsing is controlled by a servo motor..

▶Bead distance extend and retract is controlled by a servo motor.

High quality:

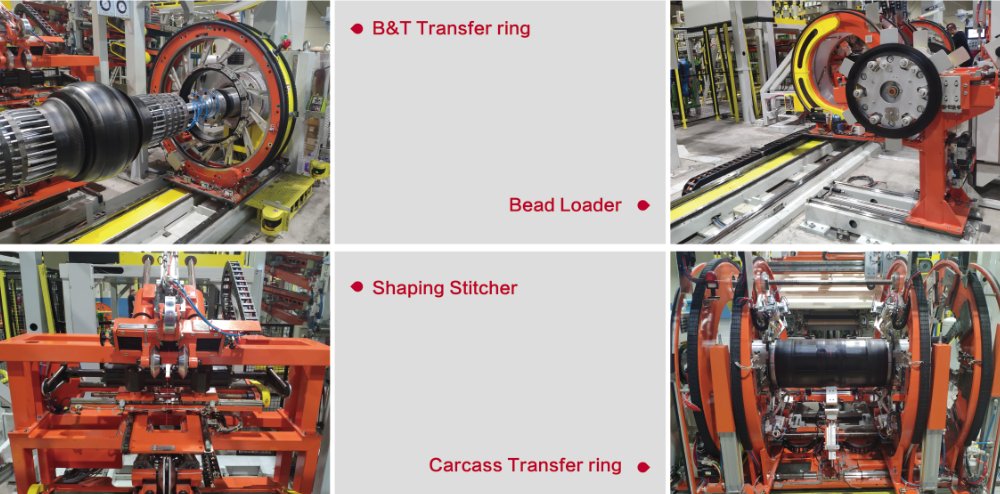

▶Bead loader is working on an autonomous full range system.

▶Bladder drum stud-pull turn-up system.

▶The shaft of shaping drum has a less deflection because of the particular structure of shaping drum station.

Delivery efficiency:

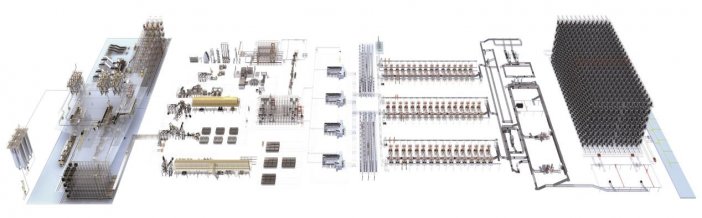

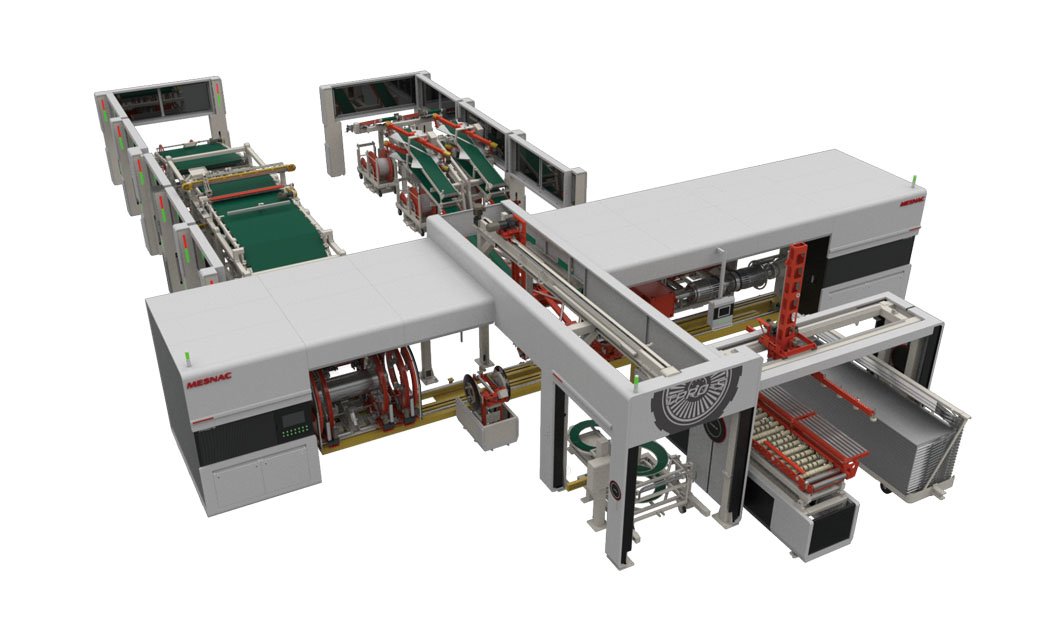

▶Machine has a modular design base on ROC platform.

▶Various configurations are available to meet the differences of the consumer demand.

User experience:

▶Life of turn up bladder on the shaping drum can be increased by 300%.

▶lts convenient long-distance manitenance function reduces manpower cost.

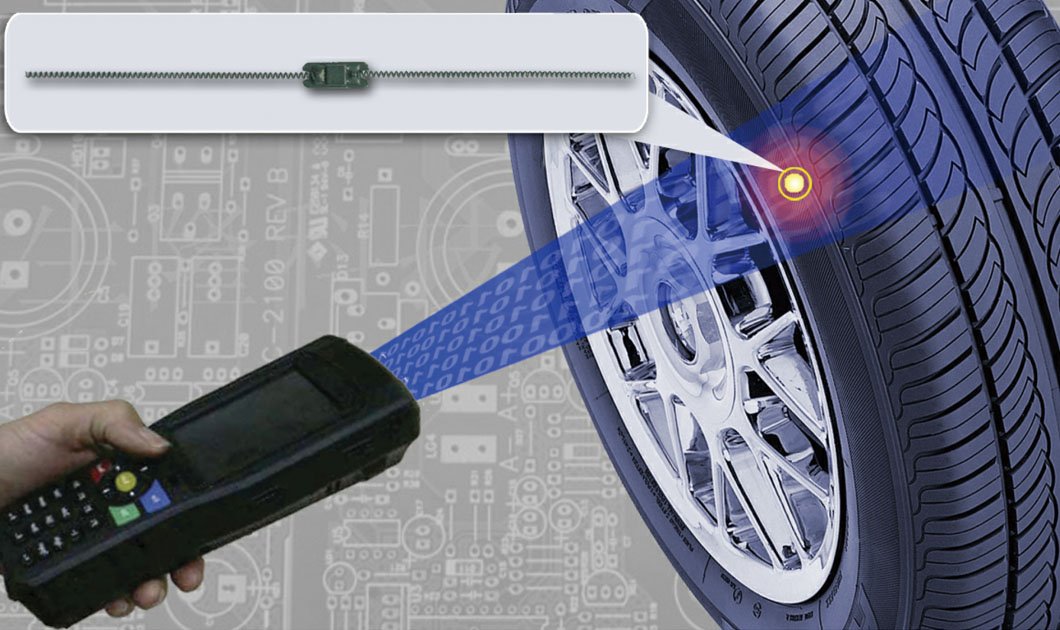

High stability: failure rate ≤0.2%,sealing ring is more resistant to time and wear. equipment will be more steady and durable

High quality: Bead distance is more accuracy, standard configuration on gear rack , transfer rings more stable motin and more durable.The effect has proved for Green tire stitch and specially for Sidewall

Low operating cost: two skilled operators and 500 tires daily output,footprint 14m*20m, Replacement takes less time