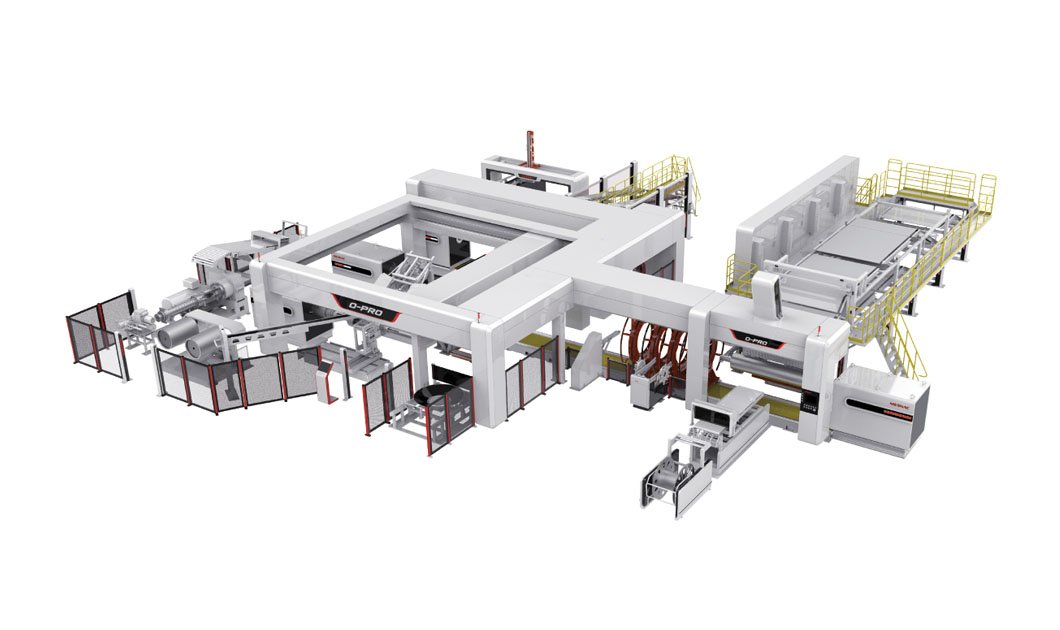

● Adopting international advanced control system, automatic operation of equipment, guarantee minimum downtime

● Splicer quality detection、surface impurities detection and online width detection systems can be selected

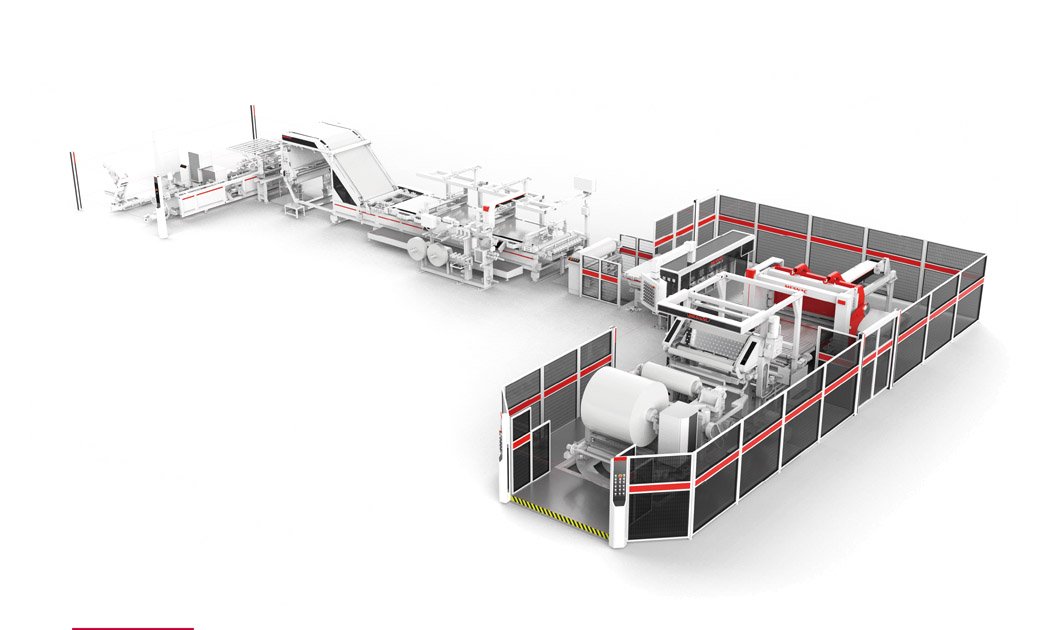

● Let-off device with rotating double stations or side by side double stations can be selected, automatic splicer of let-off materials

● Let-off automatic centering system, cold trimming or hot trimming device can be selected

● Use pulling device,servo drive,which can guarantee the accuracy of pulling

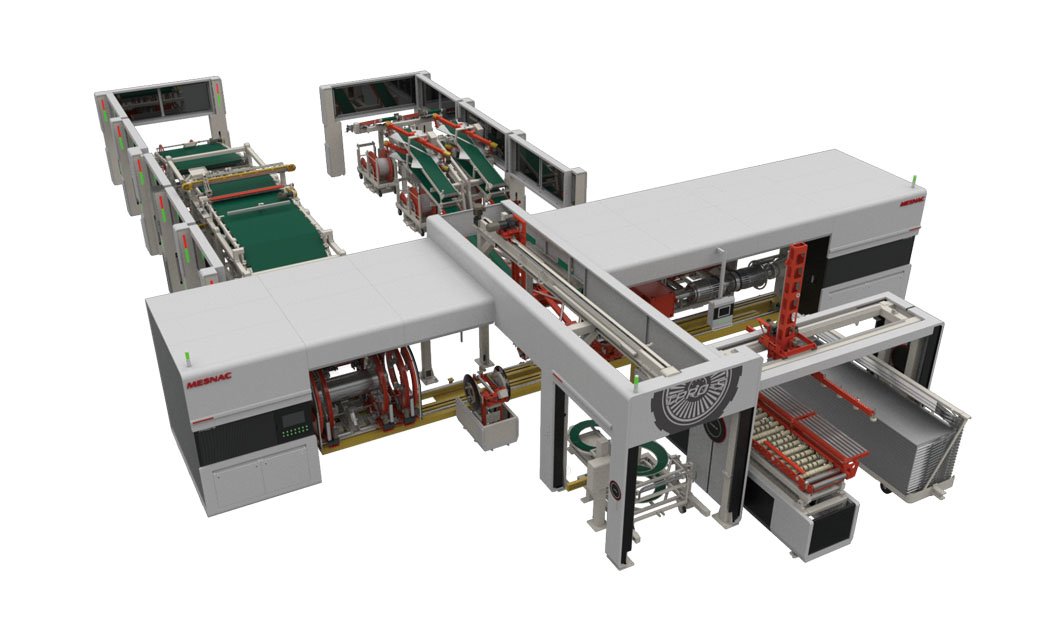

● Guillotine type cutter or disc type cutter can be selected

● Automatic splicer device adopts two sets of special pulley would splice carcass plies from two sides and the most advanced automatic deckle and rectifying form

● Flexible edging-wrapping structure, and can also choose hot application of flat strip or profile strip, which can meet different process requirements

● Gum strip applying can choose mechanical or automatic deviation rectification

● Customization of wind-up device based on customer requirements and automatic wind-up device can be selected, which can realize automatic cutting、automatic tow material、automatic change station

● SCADA system

● Equipment health management

● Perfect quality standard system, standardization modularization concept, equipment runs steadily and reliably;

● Remote diagnosis and maintenance can be selected

● Guarantee short-term recovery of customer's investment

● Perfect security solution, CE authentication