Recently, the latest issue of "European Rubber Journal" (ERJ) announced the 2018 global rubber machinery company sales revenue rankings. MESVAC shares ranked third in the world, with an increase of 6% over last year. MESNAC has been ranked among the top three in the world for eight consecutive years, with quantitative changes and qualitative leaps. The technical strength is no longer what it used to be, and smart manufacturing has taken the lead in the industry.

Relying on its unique advantages in product lines, MESNAC has made outstanding achievements in the field of smart manufacturing in recent years. It is understood that as early as 2014, MESNAC took the lead in putting forward the concept of "smart factory" in the rubber industry, and in 2015 formed a technical roadmap for tire smart factory. In November 2016, the world's first tire smart demonstration factory was put into production under the general planning and general contracting of MESNAC. In November 2017, MESNAC led the establishment of the China Smart Manufacturing and Standardization Alliance, and initially formulated six intelligent manufacturing standards. In September 2018, the first intelligent mixing plant in the rubber products industry contracted by MESNAC was put into operation. Based on the previous accumulation, the world's first "Tire Smart Factory Experience Center" built by MESNAC was also opened in 2018, in order to allow customers to intuitively experience the improvements brought by smart manufacturing.

In recent years, the introduction of MESNAC smart equipment has accelerated significantly, from the early automatic small chemicals weighing system to the recent PS2A PCR tire building machine, the third-generation TBR dynamic balance testing machine, the TPRO-S TBR tire buildinging machine, CPS curing macbine and single station X-ray machine, etc. Moreover, the relevant person in charge said that MESNAC will also launch new products and some new technologies such as the OTR tire building machine and the sixth-generation small-angle cutting machine in this year.

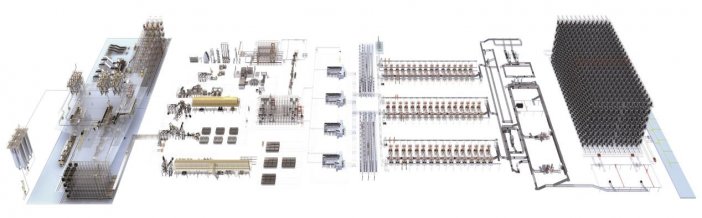

So far, MESNAC has mastered part of the core technology of tire smart manufacturing, and has accumulated more successful experience in automation, intelligent control, machine vision, human-computer interaction, equipment health management, energy saving and environmental protection and safety and reliability. At present, MESNAC can provide the rubber industry with a three-layer solution of smart equipment, smart workshop and smart factory.

In the future, MESNAC will integrate superior resources, continue to provide differentiated and intelligent solutions for global users, promote the iterative upgrade of intelligent manufacturing, and make greater contributions to the development of the industry.