On September 17, the grand opening ceremony of MESNAC Smart Factory Experience Center & 2019 New Product & New Technology Release was held in Jiaozhou, Qingdao. Liu Mingxian, deputy Mayor of Jiaozhou, attended this event, as well as Wang Yimin, the head of the Science and Equipment department of China Petroleum and Chemical Industry Federation, Zhang Hongmin, the president of Shandong Province Rubber Industry Association, Yuan Zhongxue, the deputy director of National Engineering Research Center for Rubber and Tire, He Ning, the chairman of MESNAC, and other leaders and honored guests from the global rubber industry. The conference was hosted by Liu Feng, vice president of MESNAC.

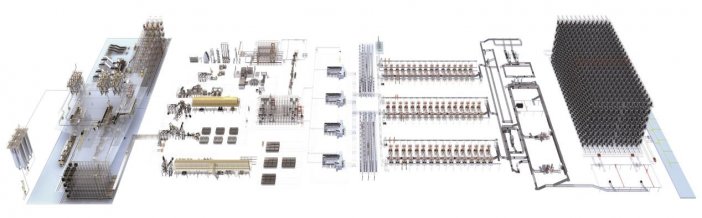

It is learned that MESNAC Smart Factory Experience Center is by far the world's first intelligent manufacturing experience platform for rubber and tire enterprises, also a product testing and technology upgrade platform, and a vivid, dynamic, and leading experience center. As a result, the Experience Center has created a new practice pattern for industrial manufacturing. Many products, technologies and systems in this center are first created in China, even in the world. The purpose of this center is to help rubber and tire enterprises to simplify management, improve quality and efficiency, reduce production costs, and be more environment-friendly in order to make higher quality rubber and tire products.

As chairman He Ning said, the reason why MESNAC has the ability to build the Smart Factory Experience Center is that MESNAC has accumulated a great deal of successful experience in three aspects over the years. First, MESNAC can provide 80% intelligent equipment for tire production. And compared to other equipment suppliers, MESNAC has the most in-depth understanding of the techniques in tire industry. Second, over the past 20 years of practice and exploration, MESNAC has completed its knowledge reserve and product-supply capacity in seven separate technical framework layers during the practice of project delivery and product development. Third, MESNAC has an extremely profound understanding of industry standards. For instance, MESNAC has led and participated in developing many industry standards involving industry equipment, information technology, RFID, and other fields. Also MESNAC initiated the China Tire Smart Manufacture and Standardization Alliance etc.

According to the introduction by rotary president Yu mingjin, with the aim to help rubber and tire enterprises to make excellent products, the criteria includes simplifying management, improving quality and effectiveness, reducing production costs, and becoming more environment-friendly. The principles of the smart factory include the optimization of unified norms, stability and reliability, human-machine coordination, automatic intelligence, and overall costs. The implementation basis includes stable quality, modular design and unified standards. These are realized by combined solution with technologies such as application informatization, logistics automation and smart control. MESNAC smart factory strives to promote the digitization of all factors in tire production as integrated solution in core measures. At present, MESNEC can provide customers with three-level solutions ranging from smart equipment, smart workshop to smart factory.

At present, MESNAC has successfully delivered two automatic smart factories and finished about 30 projects of digital workshop construction or transformation. Guan bingzheng, vice president of MESNAC elaborated on the company’s advanced practice in intelligent manufacturing and the actual changes in tire enterprises nowadays brought by smart manufacturing, taking a 2-million-sets TBR tire plant as an example.

At first, in terms of reducing labor, with the help from intelligent operation, smart factory can greatly reduce the level of difficulty in operation and management, improve the operation efficiency, and provide solutions on the level of visual equipment by applying the Mixed Reality technology, resulting in a remarkable decrease in training costs. As of efficiency improvement, through artificial intelligence scheduling, smart factory can achieve continuous production along with a decline in invalid production time by more than 5% and an increase by more than 3% in the production of stand-alone equipment. Besides, smart factory can improve production quality by a large degree through quality correlation analysis and correlation algorithm analysis of production process, techniques, and raw material on the basis of big data sorting and analysis to get the most critical factors that affect product quality. In the fourth aspect it can save a large amount of energy and then impressively reduce costs by virtue of the staggering production scheduling arranged by artificial intelligence. Finally in the aspect of warehouse management, MESNAC’s smart factory has the ability to eliminate blind spare parts procurement, resulting in a cost reduction of 15 million RMB specified for purchasing spare parts each year through equipment failure prediction and health management, and to maintain relative equipment in advance according to the situation of equipment deterioration and by so to increase the life of related components by 15%.

In the meeting, MESNAC also released Integrated Mixing Solution, including workshop production automation, workshop logistics automation, workshop digitization and informatization, workshop management and intelligent service. By using integrated solutions provided by MESNAC, smart factory can save considerable money on labor costs because of automated production processes, such as auto bag placing, auto bag making, auto bag sealing, auto bag stacking, polymer handling assistance, open mill auto-blending, one-step mixing system, auto mixer feeding, and auto storage; It can effectively improve production efficiency by introducing failure prediction mechanism and save time in machine feeding; it can effectively eliminate environmental problems by taking burning and biological method; and can realize high-precision weighing, quality management, and mistakes prevention in material arranging.

With regard to intelligent equipment, MESNAC has put its emphasis on mainly introducing its new generation intelligent Uni-stage TBR Tire Building Machine -- TPRO-S, a solely developed machine. With the five aspects of high efficiency, modularization, intelligence, informatization and automation as its core, this equipment is the 6th model of its kind after years’ continuous improvements, with37 items of reforms and innovations. It has achieved tremendous breakthroughs in several aspects of core technology, including self-perception and self-adaptive equipment, flexible HMI, and preventive maintenance. Those critical achievements have made MESNAC acquire the ability to practically meet the requirements of tire enterprises for intelligent and automated uni-stage TBR tire building machine, and to effectively improve the building efficiency and quality level of TBR tires, and to increase productivity by 30% to 40% as well as help customers increase revenue by about 30 million RMB each year compared to traditional building machine.

As for the aspect of intelligent techniques, VIS, which stands for Visual Identification System, originated from MESNAC Europe Research & Technical Center, is of great significance in improving the uniformity by detecting the radial run-out of the drum, as well as the accuracy of splicing, the width, the quality of various components online, the radial run-out of the green tire, and the position of tire bead.

MASNEC Smart Factory is an integrated solution that is based on linkage and coupling, and driven by data, most importantly with knowledge as its core. The current Experience Center is just the first phrase of the whole project, and MESNAC will continue to upgrade according to customer demands and constantly explore how to combine equipment, logistics, and informatization, including artificial Intelligence and Big Data, to help our clients reduce costs, improve quality, and produce agilely. In the future more factories will step into smart manufacturing, and MESNAC will continue to provide more optimal integrated solutions.