On Sept. 21th, PS2A PCR Tire Building Machine, designed independently by MESNAC, was released on The 17th International Exhibition on Rubber Technology in Shanghai. PS2A, with six new technologies such as synchronous turn-up filling the gaps in the domestic field and the cycle time being less than 40s, is the most intelligent building machine designed independently in China, and it has reached the advanced level globally.

Zhu Hong, Director of Technical Committee of China Rubber Industry Association (CRIA)

Companies, suppliers, experts and media in the rubber and tire industry all over the world attended the product launch of PS2A PCR Tire Building Machine. Zhu Hong, Director of Technical Committee of China Rubber Industry Association (CRIA) indicated that MESNAC has accumulated rich experience on R&D of building machine with the development of China’s rubber industry. In intelligent process of the rubber industry, the high-quality equipment is wanted to realize craftsmanship and quality control. PS2A, with its new intelligent technologies, will guarantee the production of high-quality tire and thus promote technical progress of the rubber industry.

Liu Feng, Vice President of MESNAC, hosts the product launch of PS2A PCR Tire Building Machine

As is well-known, smart manufacturing is the developing trend of the rubber and tire industry, and the R&D of intelligent equipment is urgent at present. To meet the needs of the development of rubber industry, MESNAC has designed PS2A PCR Tire Building Machine based on the experience accumulated in the past years. PS2A PCR Tire Building Machine, with two drums and three working positions, can be operated only by one operator. The rim diameter is about 14″~ 22″, and the machine layout is 15.6m×10.5m×3.58m. PS2A PCR Tire Building Machine is suitable for SOT&TOS, and its cycle time is less than 40s(205/55 R16(1ply,1JLB)).

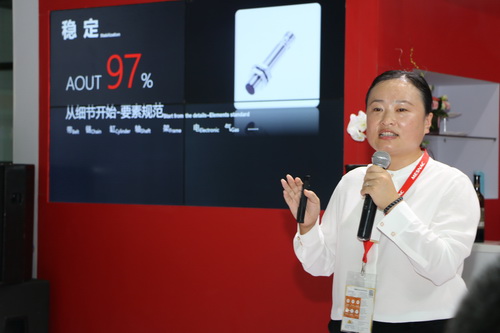

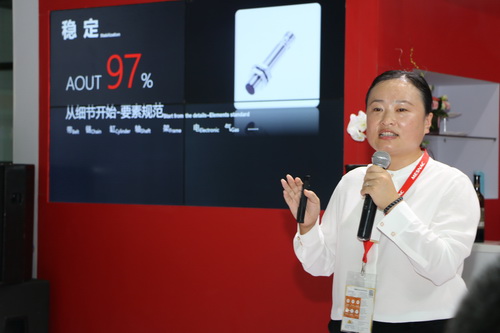

Yang Huili, General Manager of PCR Building System Division introduces PS2A PCR TBM to attendees

PS2A PCT Tire Building Machine can provide customers with service of higher quality, higher efficiency, higher stability and higher availability with the five strengths shown in the following.

Firstly, PS2A PCR Tire Building Machine, the perfect integration of technology and art, ensures the manufacturing of high-quality tire. Aiming to satisfy customers’ need for producing high-quality tire, the R&D team upgraded and made breakthroughs in a series of technologies such as synchronous turn-up with isometric force and space, belt drum servo control, belt transfer ting auto-adjusting technology, PA auto-application technology and etc., providing technical guarantee for manufacturing high-quality tire.

Secondly, the single cycle time of PS2A PCR Tire Building Machine is less than 40s, which is the leading level in the tire building field. Building efficiency and quality are the core concerns of tire manufacturer. MESNAC has always pursued the optimal balance point of building efficiency and building quality and it finally made it. PS2A PCR Tire Building Machine not only makes breakthrough in the cycle time, but also ensures the stability of equipment to produce high-quality tire.

Thirdly, the maintainability of PS2A PCR Tire Building Machine increases significantly and the invisible cost reduces by 50%. By modularization and standardization design, the structure of PS2A is more unified and thus the maintenance of PS2A becomes easier. Meanwhile, with functions like prescriptive fault diagnosis, part visualization, paperless spare parts management and etc, PS2A realizes the high convenience of equipment maintenance.

Fourthly, PS2A PCR Tire Building Machine is characterized by its high reliability and high stability, and the AOUT is more than 97%. With reliability test of materials, special research, virtual simulation, standardized assembly of parts, 8D quality control and etc, the reliability and stability of PS2A are ensured.

Lastly, PS2A PCR Tire Building Machine reaches the advanced level on the aspect of intelligence in the tire building field. With technologies such as belt drum servo control, belt transfer ring auto-adjusting technology, PA auto-application technology, tread automatic splice and etc, PS2A realizes the automatic adjustment of specification. Meanwhile, PS2A combines the innovation of mechanical structure with software development, building a bridge of communication between the operator and the machine.

PS2A PCR Tire Building Machine is mainly applied for PCR shaping, with high degree of automation, high shaping efficiency, high quality of green tire and wide shaping range; there are advantages of high stability, operability and maintainability. Successful R&D of PS2A PCR Tire Building Machine is indispensable from the rich experience MESNAC has accumulated in the past years.

Firstly, MESNAC has cooperated with more than 30 customers at home or abroad and has accumulated the practical experience in over 200 projects. In R&D of PS2A, MESNAC set up a professional team that summarized 210 common factors affecting the stability and reliability, and solved the problems in the R&D.

Secondly, based on the leading position in the field of rubber machinery, MESNAC has learned precious lessons and accumulated rich experience in the cooperation with international high-end tire companies. In R&D and production of PS2A, MESNAC combined the needs of customers with its own strengths to realize the perfect integration of technology and art.

Thirdly, MESNAC has applied the modularization design to R&D of PS2A to make its structure simpler and improve the efficiency.

Last, MESNAC has established the technical platform to guarantee the stability of the whole producing process. The modularization base, general standard base and design specification of typical structure highly improve the stability of the technology, the material base, the standard part base, general part base and the purchased part base improve the stability of the manufacturing process, and the standardization of drawing, installation, debugging and examination ensures the stability of operation in the whole process.

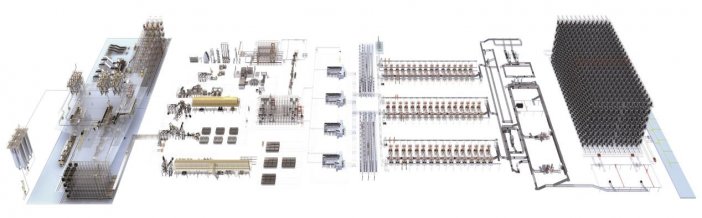

PS2A PCR Tire Building Machine is one pearl MESNAC has contributed to the rubber and tire industry in tire smart manufacturing. MESNAC has made great efforts to promote tire smart manufacturing in most fields including mixing equipment, semi-products, curing equipment, testing equipment and etc. Launch of the intelligent equipments will not only improve MESNAC’s ability to develop smart factory, but also promote the process of smart manufacturing in the rubber and tire industry.

Product launch of PS2A PCR Tire Building Machine