● High automation

● Simple operation and program monitoring

● Tidiness of laminations and accurate weighing

● Compact structure and easy maintenance

● Batch can be tracked

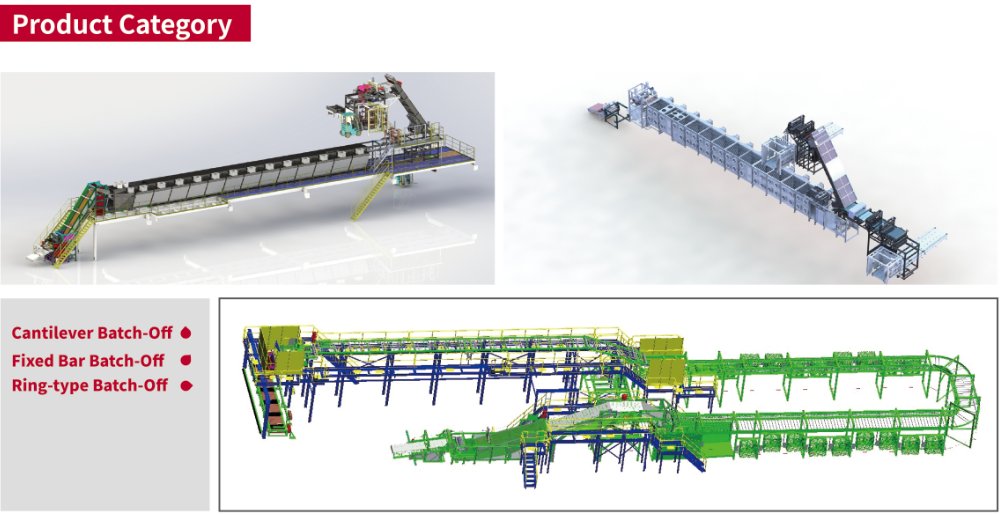

The batch-off line is the matching equipment for the mixer. It is made up of modern mixing down-stream together with mills or TSR. The line can accomplish functions for taking off、marking、strip cutting、dipping、cooling、stacking、weighing and so on. It is widely used in the tyres and products industry.

● High automation

● Simple operation and program monitoring

● Tidiness of laminations and accurate weighing

● Compact structure and easy maintenance

● Batch can be tracked

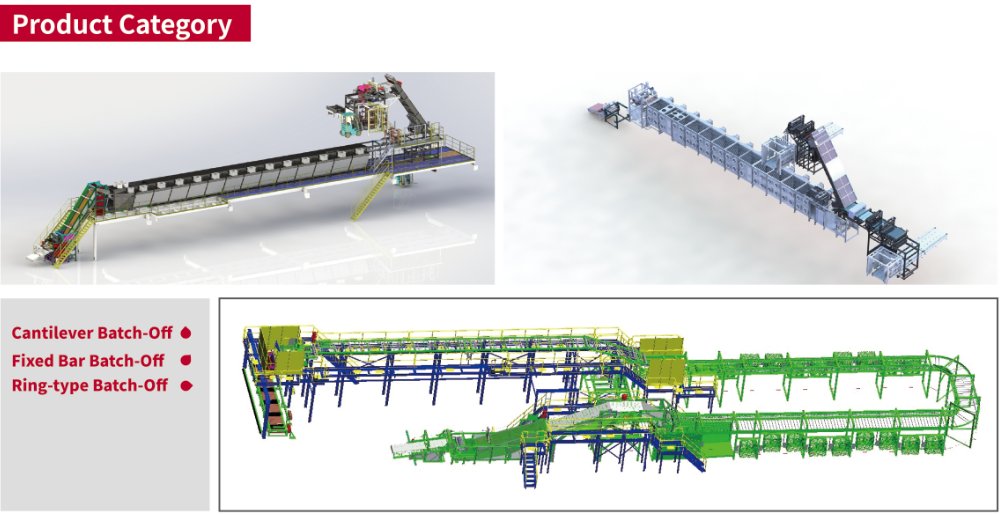

FAR20-S is new generation automatic small chemical weighing system, with higher productivity, increased weighing accuracy and fast delivery on site. It helps to ensure product quality, reduce production cost and improve the working condition.

More>

More>

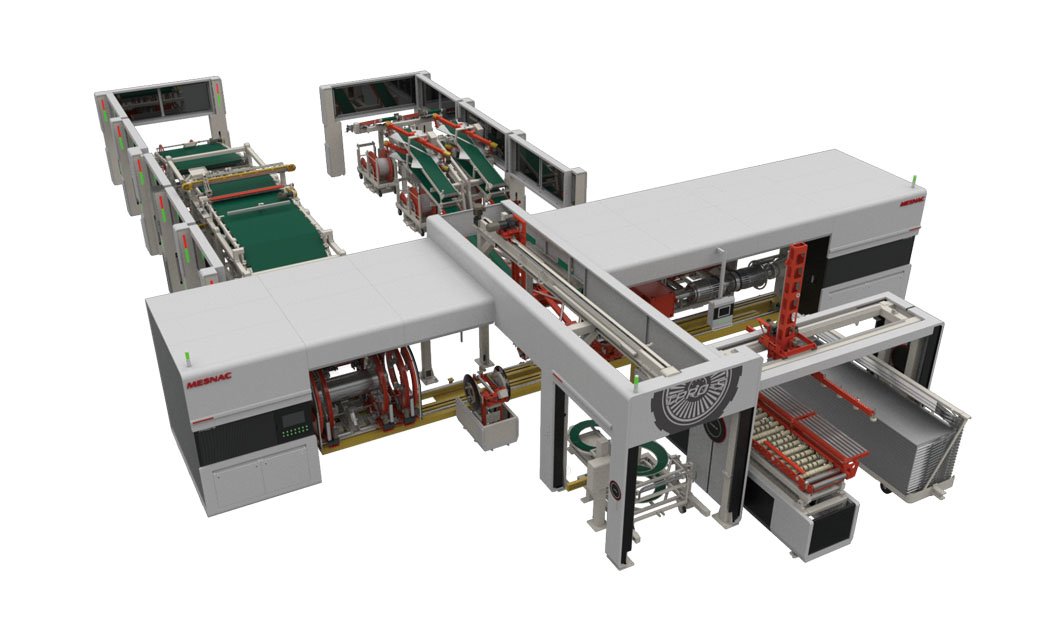

highly automatic model with short cycle time, high output, wide tire codes range, good tire quality, and rapid tire code change function

More>

More>

Applicable tire size: TBR: 20~24.5 inch LTR: 16~20 inch Shaping drum: Applicable for both mechanical and bladder drum

More>

More>

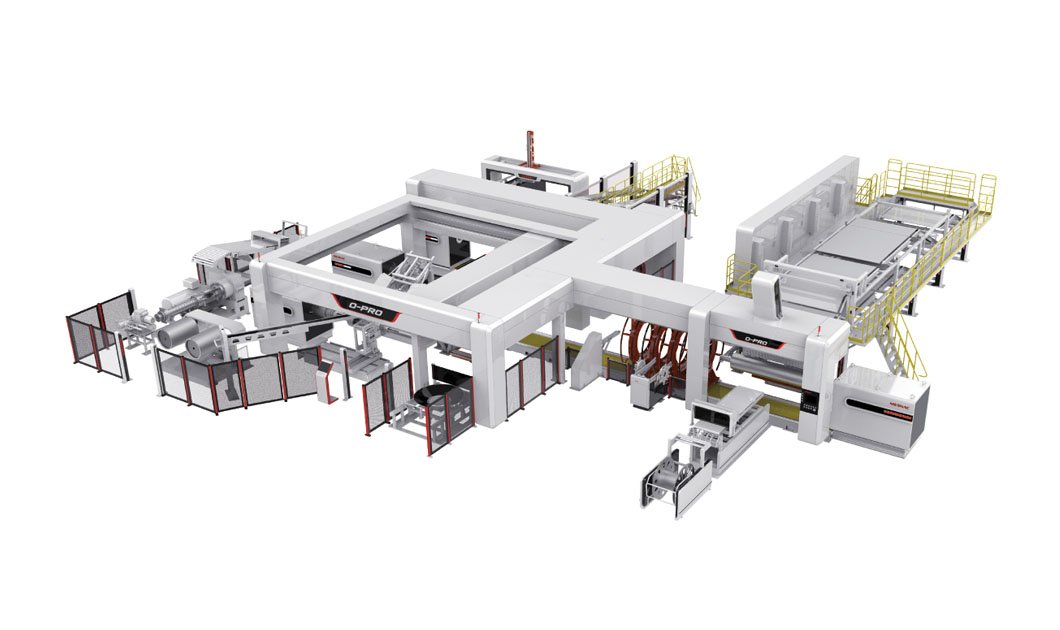

lt is the third generation of OTR TBM , independently developed based on the MESNAC ROC TBM R&D platform. Focus on the diversified building requirements and efficiency improvement of 20-25"small and medium sized OTR tires.

More>

More>

Square column + linear guide rail; Fully independent control of left and right; Separation of squeeze and guidance is more conducive to accuracy maintenance;

More>

More>

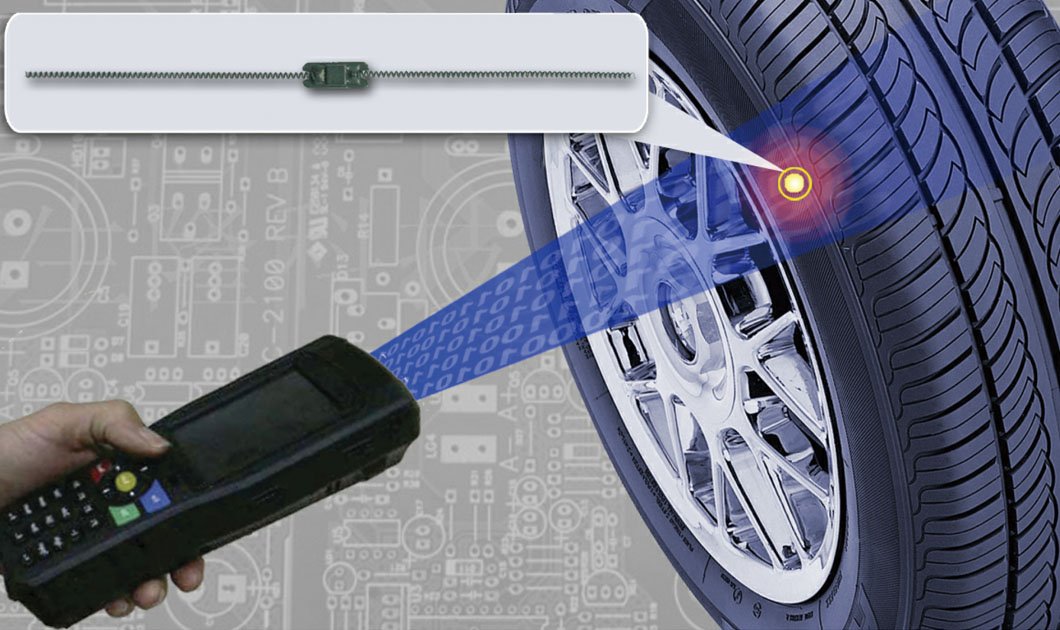

MESNAC supplies a whole solution for RFID tire from aspects of RFID tire tag series products, RFID tire production automatic equipment, informatization system, etc.

More>

More>

EMEAK Region (Europe, Middle East, Africa & Korea):

E-mail:emeak@mesnac.com

Greater China Region:

E-mail:market@mesnac.com

Americas Region:

E-mail:americas@mesnac.com

AI Region (Asia):

E-mail:asia@mesnac.com