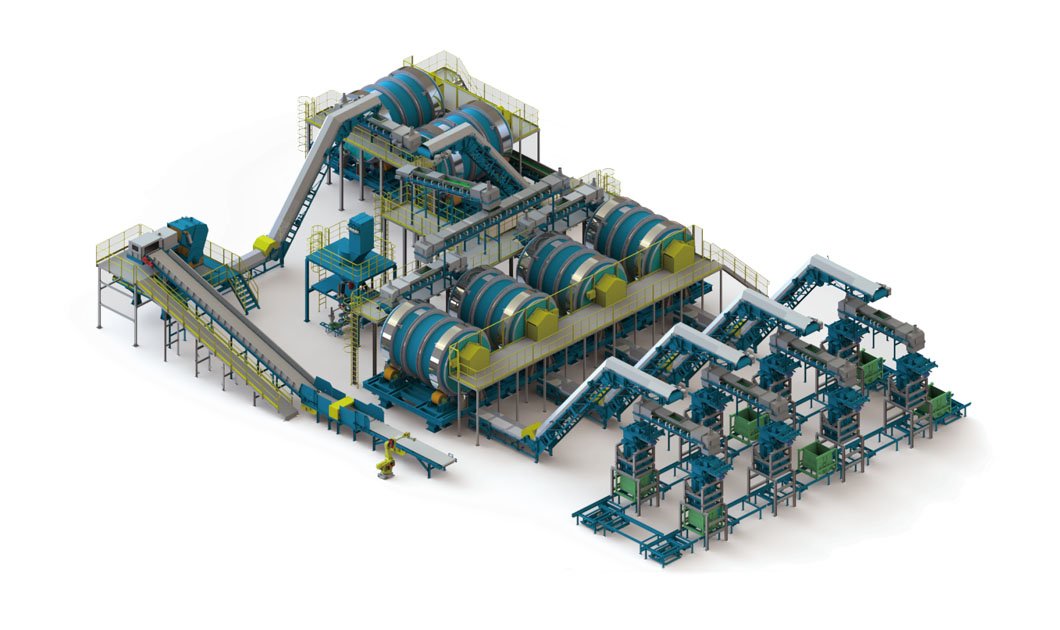

This system is used to grind the standard rubber bales used in the mixing workshop into small granules. After grinding, the small granules will be blended for homogenization to ensure the quality of the final product to be stable.

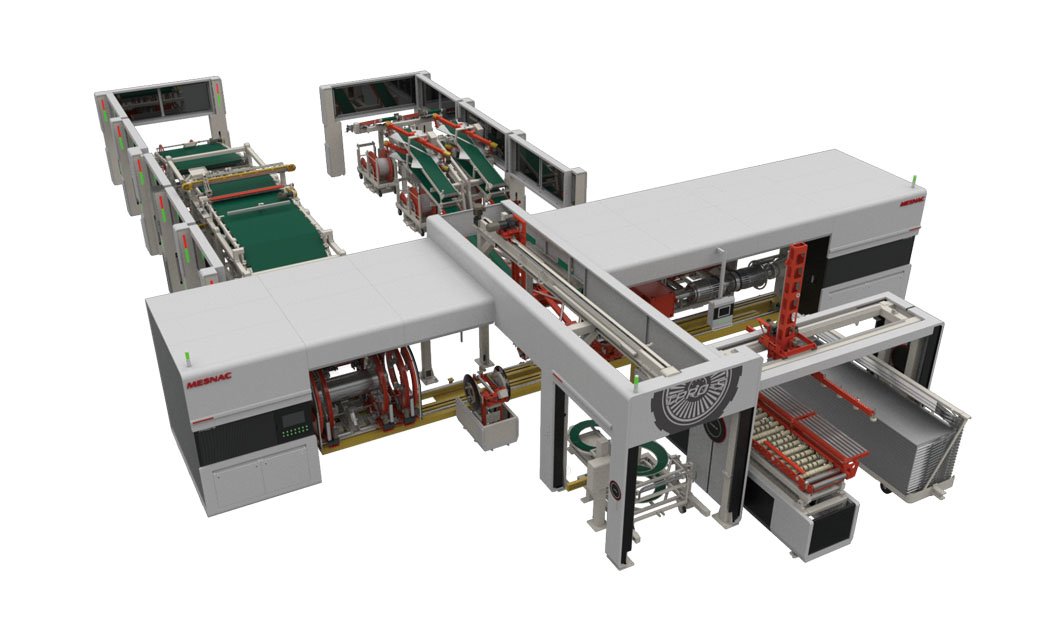

Being small granules, the rubber can be automatically transported, dosed and discharged to reduce the labor load of the operator and to increase the automation level of the rubber introduction system.

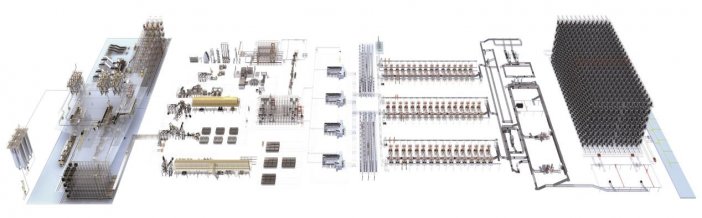

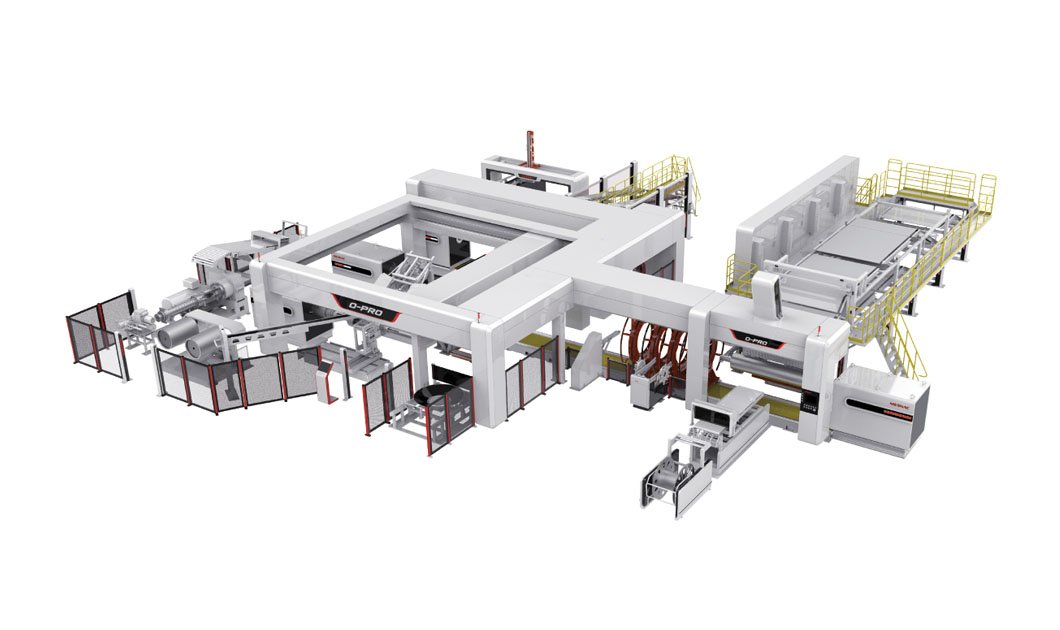

The main equipment of this system includes the shredder, the blending drums and the anti-sticking system. The auxiliary equipment includes the conveyors, the ventilation and weighing system. All these equipment will be integrated by the automation system into an automatic rubber processing system to fulfil the requirement of the production.

This system can be used in tire factory, rubber product factory and other industries related to rubber processing. It can be used as a rubber feeding system, and also can be used as an auxiliary system to fulfil high precision rubber dosage.

With different size, the shredder can satisfy the requirement of different plant scale, and can also be used for other industries.