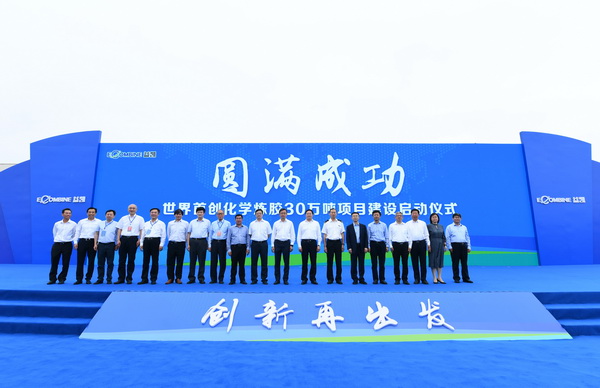

On June 9, the construction of the 300,000 tons chemical rubber mixing project of Ecombine Advanced Materials CO., Ltd. officially started, which means that the revolutionary green new material EVE rubber industrialization has entered the fast lane. The new chemical rubber mixing process technology belongs to the original innovation of the rubber industry. The industrialization of this technology is expected to greatly improve the performance of rubber tire products and promote the rapid iterative upgrade of the entire industry.

China Petroleum and Chemical Industry Federation Deputy Secretary and Vice Chairman Fu Xiangsheng, Vice Chairman Li Bin, Party Member and Deputy Secretary-General Hu Qianlin, Qingdao University of Science and Technology Party Secretary Ma Lianxiang, President Chen Kezheng, Vice Chairman of China Rubber Industry Association Xu Wenying and corporate guests from related industries attended.

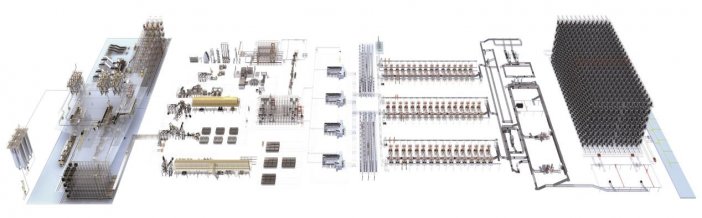

The project is located in Qingdao Dongjiakou Economic Zone. It is planned by the National Engineering Research Center for Rubber and Tire, and first international invented by EVE Rubber Research Institute; Ecombine Advanced Materials CO., Ltd.undertakes its engineering technology development and industrialization construction.

The project uses a completely self-developed new chemical mixing technology, subverting the rubber and filler physical dry mixing method that has been used in the rubber industry for a hundred years, breaking through the traditional classic wear&tear theory in the field of rubber materials, and completely breaking the the "devil's triangle" law, which troubled tire industry in the world for many years, has been commended as the "fourth milestone" in the field of rubber tires industry. The green new material EVE rubber produced by this technology is praised by the industry as "liquid gold". The high-performance "liquid gold" tires made of this material, its wet skid resistanceh are reached EU Labeling Regulations Class A Standardand, and the rolling resistance index reached level B or above, and its wear resistance index has also been improved by more than 20% compared with traditional tires, and its comprehensive performance has reached the world's leading level.

At present, EVE rubber of Ecombine Advanced Materials CO., Ltd. has been successfully applied in the rubber tire industry, and has put more than 200,000 "liquid gold" PCR high-quality tires in domestic and abroad to supply many customers. According to the completed tire evaluation data of various models, a number of main performance indicators surpass its original tires. In addition, the four-season tires developed with this technology have excellent comprehensive performance, and their ice performance has reached the highest international level, with the wear resistance has increased by more than 40%, and the rolling resistance has been reduced by more than 30%.

Research has found that under the condition of 80km/h, the braking distance of A-class tires can be shortened by 18 meters compared with lower-class F tires, which is self-evident for personal and vehicle safety during traffic accidents; and for passenger cars in other words, if the rolling resistance of tires is increased from G to B, the fuel consumption of a car can be reduced by 560 liters when driving 100,000 kilometers. Based on the fuel price of 6 yuan per liter, the owner can save about 3360 yuan in fuel costs, and an average of 840 yuan per tire. In other words, the improvement of tire quality that has not been noticed in the past can not only greatly enhance the safety of cars during driving, but also bring real economic benefits to consumers.

Ecombine Advanced Materials CO., Ltd. is a holding subsidiary of MESNAC. After the 300,000 tons chemical mixing project is fully completed, it is expected to achieve an output value of tens of billions. It will further expand the development space of MESNAC and help the high-quality development of the rubber tire industry, create good economic and social benefits.