Crowned as the “Davos Event” in the global chemical and rubber industry, China International Rubber Industry Expo (short for CIRI Expo) was grandly held in Qingdao from October 15th to October 17th. Over one hundred exhibitors from China, Italy, Span, Thailand, Japan and other countries were present to exhibit their latest technologies and products. MESNAC won “Golden Rubber Award” at CIRI Expo and was recognized as “2014 Top Ten Leading Brands”.

MESNAC Exhibition Booth

As the leading player in the rubber machinery industry, MESNAC presents an excellent image at CIRI Expo. Consistent with the marketing slogan of “Global Technology for Local Solutions”, MESNAC highlights its comprehensive product line and global distribution of R&D, service and manufacture at the expo. Its magnificent booth attracts wide attention from visitors.

“Golden Rubber Award” Winner

Mr. Liu Yingjie (third from the right) at the Awarding Ceremony of Golden Rubber Award

“Golden Rubber Award” is known as the “Academy Award” in the rubber and tire industry. The awarding ceremony of “Golden Rubber Award” is the most important event during CIRI Expo. MESNAC was awarded with “Golden Rubber Award--2014 Top Ten Leading Brands”. The award indicates MESNAC’s leading position in the rubber and tire industry.

MESNAC is committed to R&D and manufacture of rubber machinery. It aims to provide an integrated smart solution that consolidates equipment and software and covers the entire tire manufacture process. As a leading rubber machinery supplier in the globe, MESNAC prides itself with professional R&D platform, global marketing and service network and top level manufacture center. Currently, MESNAC’s footprint is spread to over 300 tire manufacturers in more than 30 countries and regions in the globe.

Top Talk from Media

Top Talk with Mr. Liu Yingjie, President of MESNAC Greater China Region

At CIRI Expo, Mr. Liu Yingjie, President of MESNAC Greater China Region, accepted joint interview from over 20 professional media at home and abroad, including CCTV, China Daily, Huanqiu.com, China Rubber, Rubber News.com, iQilu.com, etc.

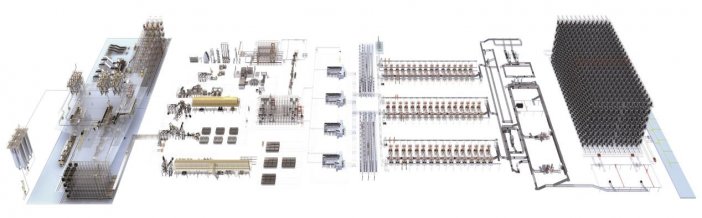

During the interview, Mr, Liu Yingjie elaborated on the global strategic distribution of MESNAC in R&D, marketing and manufacture as well as its global service network that covers Europe, North/Latin America and Asia-pacific. Meanwhile, he mentioned MESNAC’s latest R&D breakthrough in automation, intelligence and informatization solutions, such as PCR single-stage TBM, curing press, robotic arms, and automated storage and retrieval system (AS/RS). According to Mr. Liu, “the newly developed PCR automated TBM only needs one operator. The cycle time could reach 50s/tire. The latest hydraulic curing press can realize long-term automated continuous production, the operation rate of which is over 98%.”

Efforts on Smart Manufacture

MESNAC is committed to R&D of informatization equipment applicable to the rubber and tire industry. As the pioneer of building automation factory in China, MESNAC further puts forward the notion of “smart factory”, which represents an optimized consolidation of equipment, software, robots, RFID technologies, control systems, etc. MESNAC is endeavor to build a smart manufacture system that intelligently integrates all the manufacturing processes to give unique visibility into the process at all levels of the company.

At 2014 International Rubber Forum and Information Conference held along with CIRI Expo, Mr. Jiao Qingguo, General Manager of MESNAC Information Logistics Division, and Mr. Meng Xiangsheng, Sales Engineer of MESNAC Kingerobot Automation Equipment Co. were present as guest speakers and discussed MESNAC’s endeavor in smart manufacture. Mr. Jiao presented intelligent logistics system independently developed by MESNAC; it can realize automated sorting, dispatching, storage and data analysis in the tire plant. Mr. Meng discussed how MESNAC gantry robot facilitates tire manufacturers in realizing automated transportation in the factory and aroused heated discussion at the conference.